ETO Sterilizer - Krishna Engineering

Ethylene Oxide (EO/ETO) Gas Sterilizer Manufacturer & Exporter: Krishna Engineering

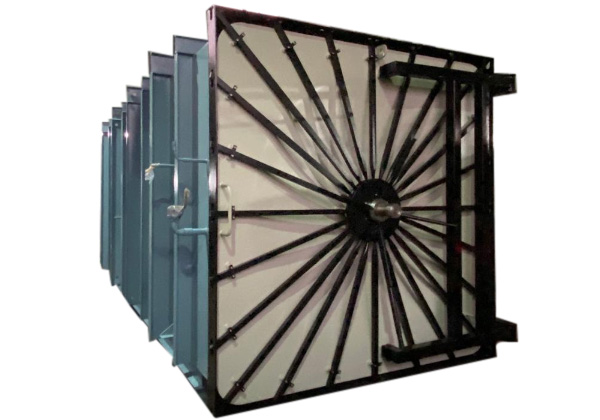

Krishna Engineering is a successful manufacturer and exporter of EO/ETO gas sterilizers. Our ETO sterilization technology gives us unmatched expertise. We provide top sterilization solutions for many industries, prioritizing safety and compliance.

ETO Sterilizer Specialist

Krishna Engineering, ETO Sterilizer Specialists, develops sterilization tech. They use innovative design and precision engineering. Our Ethylene Oxide Sterilizers meet our clients’ diverse needs. They effectively treat bacteria in various applications.

Ethylene Oxide (EtO) Sterilization Process & Service

Ethylene oxide sterilization kills all microbes on medical products. This includes bacteria, viruses, and fungi. It is very effective. The process exposes the product to controlled Ethylene Oxide gas. This ensures proper sterilization while maintaining the item’s integrity.

Our sterilization service with ETO is synonymous with reliability and effectiveness. State-of-the-art tech controls all sterilization parameters: temperature, pressure, and gas concentration. It seeks the best results. Top, fully automated systems ensure precision and consistency. They minimize human error and maximize safety.

Types of ETO sterilizers

- Batch Sterilizers

- Continuous Sterilizers

- Tabletop Sterilizers

- Low-temperature Sterilizers

- Combination Sterilizers

Applications of ETO sterilizers:

- Surgical Instruments

- Catheters

- Implants

- Endoscopes

- Pharmaceuticals

Our Goal

With an emphasis on product sterilization, our goal is to provide state-of-the-art industrial ETO systems specifically suited for turnkey projects in a variety of sectors.

Our Objective

Our core values are to welcome fresh challenges, encourage creativity, and relish working together on a journey of mutual growth with our clients.

Quality of Products

Our constant goal is to offer the best eto products and services at the most affordable costs. We carefully monitor the manufacturing and operational processes in order to maximize effectiveness and efficiency

Features of ETO Sterilization:

- Single or double-door options are available. Sliding door or hinged, as per client requirements.

- Jacketed, steamy dimples for better uniformity in heat dissipation. Technology for fast sterilization cycle with lower operating costs.

- A gas deflector device is fitted to ensure gaseous sterility at low temperatures, too.

- Easy to operate and safe with auto cycle mechanism.

- The performance of this requires no professional staff.

- It only requires domestic supplies.

- Power consumption is very low.

- ISO 11135 real-time data/time monitoring system; this is optional.

- Design: CGMP, GAMP, FDA, and Australian guidelines

- Sizes can be made to order.

Advantages of Krishna Engineering's ETO Sterilizers

- Precision and Control: Our sterilizers are designed to control sterilization parameters with precision.

- Durability: Our sterilizers have a durable, high-grade stainless steel structure. It resists wear and corrosion.

- User-Friendly: Our sterilizers are fully automatic. They need no manual work. So, they are very easy and efficient to use.

- Versatility: Our sterilizers are used in many industries. They work on medical devices and in pharmaceuticals. Their pressure is 1.0 to 1.5 kg/cm², with a temperature of 45°C.

- Safety: The triple-wall insulation and controlled environment ensure maximum safety. They protect both the operator and the products inside the sterilization chamber.

An establishedmanufacturer & supplier of hospital sterilizer EO/ETO (Ethylene Oxide Gas Sterilizer) for hospitals, labs, and surgeons by Krishna Engineering, India.