Batch Type Steam Sterilizer Ahmedabad | Best Batch Type Steam Sterilizer Manufacturer, Exporter & Supplier in India: Krishna Engineering

Knowing the Benefits of Batch Type Steam Sterilizers

Benefits of choosing a Batch type Steam Sterilizer Manufacturer

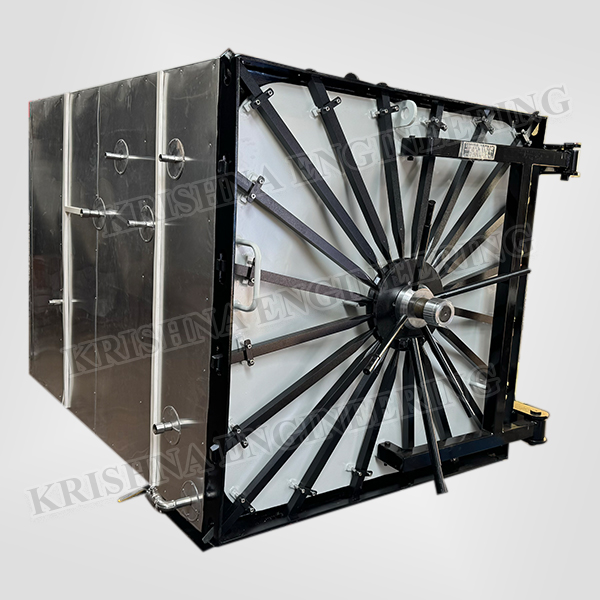

Autoclaves, or batch-type steam sterilizers in India, can process a set number of items at once. They work by enclosing the objects in a chamber and using pressure to introduce steam. This technique works well for sterilizing many items. These include food, lab tools, and medical devices.

Batch type Steam Sterilizer for spices and herbs

| Type Of Sterilizer | Steam Sterilizer |

| Brand | Krishna Engineering |

| Material | SS304 / SS316 |

| Automation Grade | Fully Automatic |

| Warranty | 2 Year |

| Chamber Dimension | As per design |

| Chamber Volume | 200 to 6,000 liter / 0.2 to 6 cbm |

| Working Pressure | -0.600 to 2.5 kg/cm² |

| Insulation Wall | Triple Wall |

| Temperature Range | 90-150 Degree C |

| Sterilization cycle time | 1 hour |

| Automation Grade | Fully Automatic with password protection |

| Size | Customize size available |

| Documentations | Inclusion of necessary documents |

How It Operates

- Insert sterilizer items into the chamber of the device during loading. After that, the experts seal the compartment and start the cycle.

- The sterilizer heats the steam and chamber to a set temperature, usually 121°C to 134°C (250°F to 273°F), during pre-heating.

- Sterilization: Pressure is exerted while steam is injected into the chamber. By denaturing their proteins, bacteria are killed by this process.

- Drying: After sterilization, the steam is removed. Then, the goods are dried with heat or a vacuum system.

- Unloading: The sterile objects are taken out of the chamber after it has been opened.

Advantage of a Batch type Steam Sterilizer Manufacturer products

- Versatility: batch-type steam sterilizer by exporter can sterilize many objects and materials.

- Control: Accurate control over the pressure and temperature during sterilization.

- Validation: It is simpler to verify and record adherence to rules and guidelines.

- Cost-effective: Perfect for establishments with sporadic sterilizing requirements or lesser volumes.

Advantages of batch-type steam sterilizer in India

- Scaling up the fermentation process is more dependable when people use batch-type steam sterilizers by the exporter by us.

- It operates easily.

- To add fermentation media, no further items are needed.

- The fermentation medium's exposure to heat can be considerably decreased using batch sterilization.

- High amounts of cell death are achieved through batch sterilization.

Additional uses of batch-type steam sterilizers in Gujarat

- Medical field : The sterilizers are quite crucial in the medical field for laboratory equipment, surgical instruments, and medical apparatus to prevent infection and ensure safety to the patients. In this respect, they find wide applications in hospitals, clinics, and dental institutions.

- Laboratories : Batch-type steam sterilizers serve to sterilize glassware, media, and several research instruments.

- Food Industry: These batch-type steam sterilizers are used for food preparation and preservation, both in jars and cans, assisting in making the food products safe for consumption and longer in life span by effectively killing the harmful microorganisms during the processing of food.

Understanding Batch type Steam Sterilizer In Gujarat

Batch-type steam sterilizer by expert supplier like us processes different materials without interruption. So, they suit high-throughput settings. These systems run continuously. Objects are continually passed through the sterilizing chamber.

- Efficiency: Its higher throughput makes it perfect for large operations.

- Automation often includes automated feeding as well as unloading systems. These minimize the need for physical work.

- Consistent Quality: Offers homogeneous sterilizing conditions to guarantee constant quality in every item.

- Space-saving: This usually takes up less room than several batch-type devices.

Several factors determine whether to choose batch-type steam sterilizers or not

Volume of Sterilization : Batch steam sterilizer supplier products are more effective for high volume requirements. Batch-type sterilizers are more suited for minor or sporadic needs.

Space & Budget : Batch units are more adaptable as well as cheaper. Batch-type sterilizers need less room and cost less.

Batch-type sterilizers are more flexible and controllable. So, they suit a wide range of materials and objects.