Ethylene Oxide (EO/ETO) Gas Sterilizer Manufacturer & Exporter

Krishna Engineering is in Ahmedabad, Gujarat, India’s top business center. It is a well-known maker and exporter of high-quality ETO Sterilizers for the medical and pharmaceutical industries. Our commitment to excellence and innovation has made us a leader in the sterilization industry.

We design ETO sterilizers. We also control them using advanced heat and humidity-sensitive equipment. Our sterilizers meet the high demands of medical and pharmaceutical uses. They work on syringes, dialysis cartridges, catheters, plastic dressings, and sutures. These products are designed to meet key industry standards. This ensures their safety as well as effectiveness.

Superior Quality Ethylene Oxide (EO\ETO) Sterilization Exporter

Our vast industrial experience lets us offer our clients, high-quality, well-designed products. Krishna Engineering will use the best raw materials and parts. This will make high-quality products that can match global standards.

Krishna Engineering is a leading maker of industrial sterilizer machines. We supply and export to industries like life sciences, medical devices, tissue banks, test labs, PPE, and herbs and spices. We are based in Ahmedabad, Gujarat. We are well known for our high-quality work. Our machines have no risk of failure.

ETO Sterilizer Product Specifications:

Krishna Engineering makes Ethylene Oxide Sterilizers for specific uses. They have a full line, all tailored for different sterilization applications. Listed below are major features of our ETO sterilizers:

| Type of Sterilizer: | ETO sterilizer |

| Brand: | Krishna Engineering |

| Material: | MS / SS304 / SS316 |

| Automation Grade: | Fully Automatic |

| Warranty: | 2 Year |

| Chamber Dimension: | As per design |

| Chamber Volume: | 1 cbm to 80 cbm |

| Working Pressure: | -0.600 to1.5 kg/cm² |

| Shape: | Rectangular |

| Insulation Wall: | Triple Wall |

| Temperature Range: | 45-65 Degree C |

| Sterilization cycle time: | 8-12 hours |

| Automation Grade: | Fully Automatic with password protection |

| Size: | Customize size available |

| Comply: | GMP, ISO 11135, ISO 13485, SCADA ETC |

| Documentations: | Inclusion of necessary documents |

| Safety | Two stage locking systems |

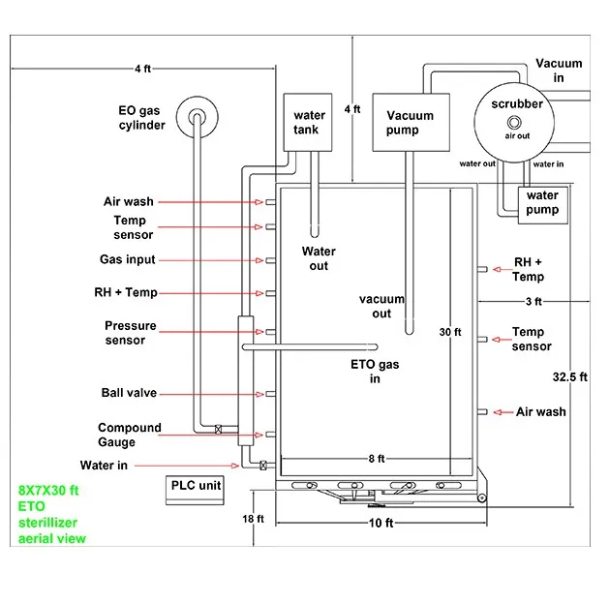

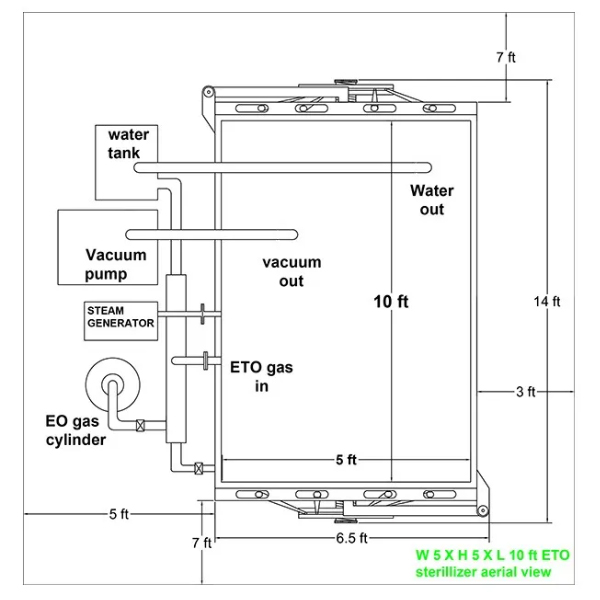

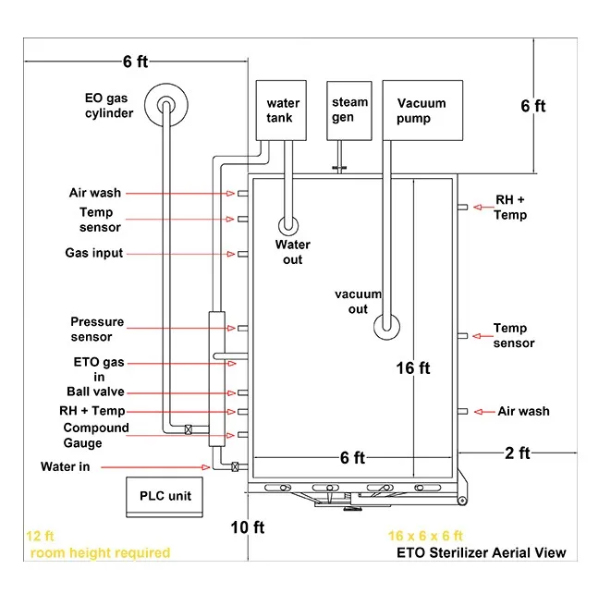

Our Ethylene Oxide sterilizers use high-quality stainless steel. It makes the apparatus strong, durable, and corrosion-resistant. Our fully automatic apparatus is simple, easy, and efficient for sterilization. With a chamber dimension of 4x4x6 ft and a volume of 2.72 m³, a whole host of products can be treated in our sterilizers.

Our ETO sterilizers have a fully automated process. It ensures user-friendliness and reliable, consistent sterilization. No continuous operator involvement is required.

| Sterilization Time: | Our machines balance thoroughness as well as speed. They have efficient processing times that meet the needs of various industries. The sterilization cycle ranges from 8 to 12 hours. |

| Working Temperature: | Our sterilizers work at 45–65 °C. They kill all microbes and keep the objects intact. |

| Negative Pressure Cycle: | It improves efficiency and safety. By keeping hazardous gases from escaping and ensuring complete sterilization, it does this. |

| Ease of Operation: | Our ETO sterilizers are easy to use. They integrate into your workflow, as they were made with user-friendliness in mind. This means that there is less of a learning curve. |

| Compact Model: | These small, powerful sterilizers are perfect for tight spaces. |

| High Efficiency: | Our ETO sterilizers maximize output and minimize energy use. They are a cost-effective and eco-friendly choice. |

Our sterilizers were designed to meet CGMP, GAMP, and FDA requirements. This ensures they are of the highest quality and comply with regulations. It gives our customers peace of mind.

Every sterilizer includes all required accessories. This guarantees peak performance and a ready-to-use solution.

ETO Sterilizer Product Safety features:

- Thermal radiation and insulated heat emission chamber

- Two steps central door locking

- Due to the negative pressure cycle, the door always remains closed at 0. Password protection

- Batch monitoring system

- In case of leakage, no gasses will come outside the chamber

- Overpressure & under pressure warning and auto prevent

ETO Sterilizer Product Applications:

- All kinds of spices & herbs industries

- Medical disposables manufacturing industries

- Hospitals, biological waste department

- Medical instruments manufacturing industries

Our Goal

Product Sterilization: We offer advanced ETO systems for turnkey projects in various sectors. They are ideal for industrial use.

Our Objective

We aim to be a top provider of modern ETO sterilization systems, for any industrial sector.

Quality of Products

Our constant goal is to offer the best of products and services at the most affordable costs. We are very careful about operational and manufacturing process effectiveness and efficiency. Thus, if you are looking for the best as well as effective quality products, choosing us can be your ideal choice, we have a wide range of products that you can choose from.

Why Choose Krishna Engineering for Sterilizers?

The features below set us apart from our competitors:

- Extensive industry experience

- State-of-the-art modern infrastructure

- Well-managed processes

- Skilled workforce

- Compact design and technically advanced equipment

- Stringent quality management systems

- Wide distribution network

- Timely delivery

- Competent cost